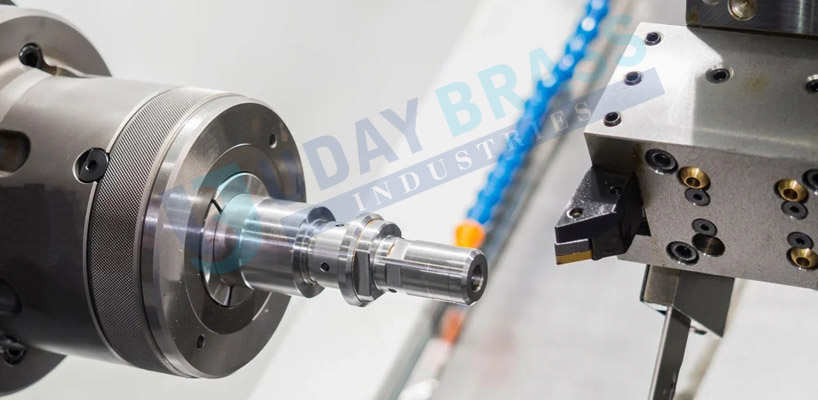

Modern & Innovative

Manufacturing Facilities

With decades of experience in manufacturing, new product development and production processes, we have devised efficient methods that increase our productivity and our clients’ profits.

Our state-of-the-art CNC equipment, operational control processes, comprehensive inspection devices, built-in quality checkpoints and no-compromise quality control systems help us improve our quality standards at low costs, maximise our manufacturing efficiency and guarantee indispensable precision turned components and fittings.

Our Capabilities

-

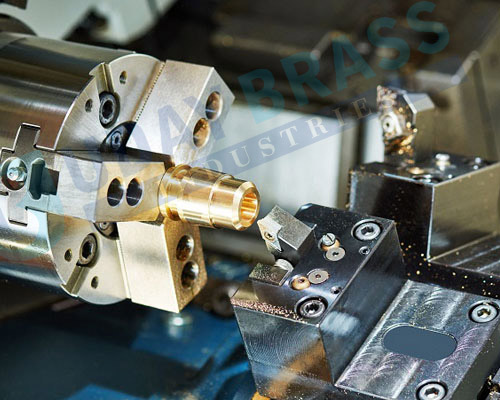

Raw Material

Brass, Copper, Stainless steel, Aluminum

and Non-Ferrous material -

Forging : Size

We excel in all types of forging, both hot and cold, providing durable and robust components for diverse applications.

-

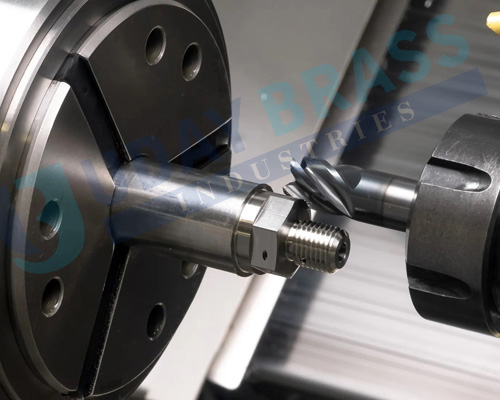

Machining

Our state-of-the-art machining facilities offer a plethora of services, including : Turning, Milling, Drilling, Threading.

-

Component Manufacturing

Dimensional Capabilities :

Outer Diameter : 5 mm to 650 mm

Length Diameter : 0.5 mm to 1000 mm -

Surface Treatment

Nickel, Chrome Plating, Silver/Gold Plating, Brass Plating, Grinding/Buffing, Galvanizing, Anodizing, Tin Coating

-

Delivery & Packaging

With our warehouse facility, we maintain an efficient supply chain, guaranteeing timely and hassle-free deliveries. Our expertise in skin packing and blister packing ensures the safe transportation of your products.